#LOW SUBSONIC SPEED NASA WINDOWS#

Optical access windows in the compressor casing are used in conjunction with nonintrusive measurements and flow visualization techniques.

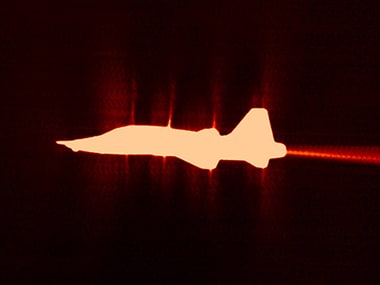

The detailed flowfield measurements will assess the emerging CFD codes as well as provide data for the development of flow models required by the CFD codes. The increased size and low speed permits instrumentation to be located directly in the compressor’s complex flow paths. The compressor rotor is driven by a 1500-hp variable speed drive motor. Airflow exiting the compressor is controlled by a throttle valve, close coupled to the collector, and discharged into the atmospheric (axial) or altitude (centrifugal) exhaust system. The axial compressor has been configured for injection of air through the stator footring, stator blades and endwalls to assess flow control. The axial compressor has a removable casing treatment under rotor one and rotor three, which allows for various tip treatment studies. Air enters the facility through a filtered roof vent, is conditioned for temperature and turbulence, and then passes through the research compressor. Designed for a 4-ft diameter axial flow compressor, W-1A can be also be restored to facilitate a 5-ft diameter centrifugal flow compressor. This unique facility provides for an increased understanding of the complex flow phenomena within the curved centrifugal channels and multi-stage axial compressors. Two 14-channel magnetic tape recorders are used for dynamic data and the LDV system measures flow path behavior. This facility is used to test compressors for gas turbine engines at conditions similar to those found in normal use as well as advanced concepts.Ī distributed data acquisition system provides on-line and post-run processing ESCORT-D handles up to 576 channels of analog inputs both steady state and discrete from an ESP system. The rig can accommodate compressors up to 20 in. Air enters the inlet plenum tank, passes through the compressor, and discharges through a throttle valve and cooling water spray before it enters the altitude or atmospheric exhaust system. The compressor can draw air from either an atmospheric intake, a 40-psig pressure source, or 10-psig refrigerated air system. The facility consists of a 6000-hp motor/gearbox which drives a research compressor at speeds up to 60,000 rpm achieving overall pressure ratios up to 30:1. This facility provides the capability for investigating the performance of advanced single- and multistage axial and centrifugal compressors, and various stage combinations over a wide range of speed, power, and mass flow. And about 54 minutes into it, Josh Brost (Account Manager, SpaceX) explains a bit more of what SpaceX is currently doing, too.Home > Facilities > Engine Research Building Turbomachinery Facilities Small Engine Components Compressor Test Facility (CE-18) In that same video, about 21 minutes into it, Michelle Munk (Principal Investigator for EDL, NASA LaRC) also describes NASA-SpaceX cooperation on Supersonic Retropropulsion (SRP) and what NASA is getting out of it, not only the other way around. To pay it forward a bit, NASA also does such test of VTVL and ALHAT (Autonomous Landing Hazard Avoidance Technology) technologies with test flights, recently for example with Project Morpheus that is interestingly explained by Jon Olansen (Manager, MORPHEUS Project, NASA JSC) in this video from ExploreMars' 2015 Humans 2 Mars conference, roughly 23:30 into it. Tests wereĬonducted at several orientations and speeds ranging from Mach numbersĠ.3, or 228 miles per hour at sea level, to Mach 5, or 3,811 miles per hour at sea level, to gauge how the first stage reacts during the Provide SpaceX with test data that will be used to develop a re-entryĭatabase for the recovery of the Falcon 9 first stage. In the wind tunnel test facility on the Falcon 9 first stage to Under a Reimbursable Space Act Agreement, Marshall conducted 176 runs According to this article on from May 2012 :

This test ( F9R 1000m Fin Flight) included all aerodynamic control surfaces that a Falcon 9 first stage would use.īut, for deceleration to subsonic regime, which these F9R Dev test flights don't yet include, SpaceX is being helped by NASA and there have indeed been wind tunnel tests (176 runs) done in NASA's Marshall Space Flight Center.

0 kommentar(er)

0 kommentar(er)